- Product features

- 1、The geometric shape of components has high degrees of freedom, and can produce complex shaped metal components in one go, just like producing plastic products.

- 2、MIM products have uniform density and good smoothness, with a surface roughness of Ra 0.80-1.6 μ m and a weight range of 0.1-300g. High dimensional accuracy (± 0.03~± 0.05), generally without the need for subsequent processing.

- 3、Wide range of applicable materials, wide application fields, high utilization rate of raw materials, high degree of production automation, simple process, and can achieve continuous large-scale production.

- 4、The product has stable quality and reliable performance. The relative density of the product can reach 95% to 99%, and it can be subjected to heat treatment such as carburization, quenching, and tempering. The product has high mechanical properties such as strength, hardness, and elongation, good wear resistance, fatigue resistance, and uniform organization.

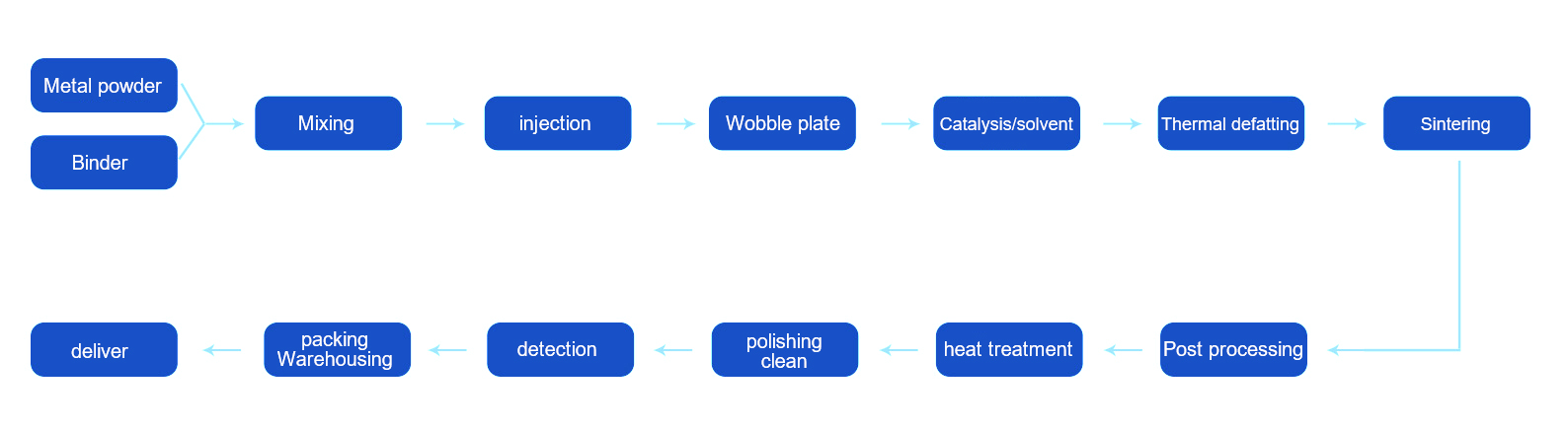

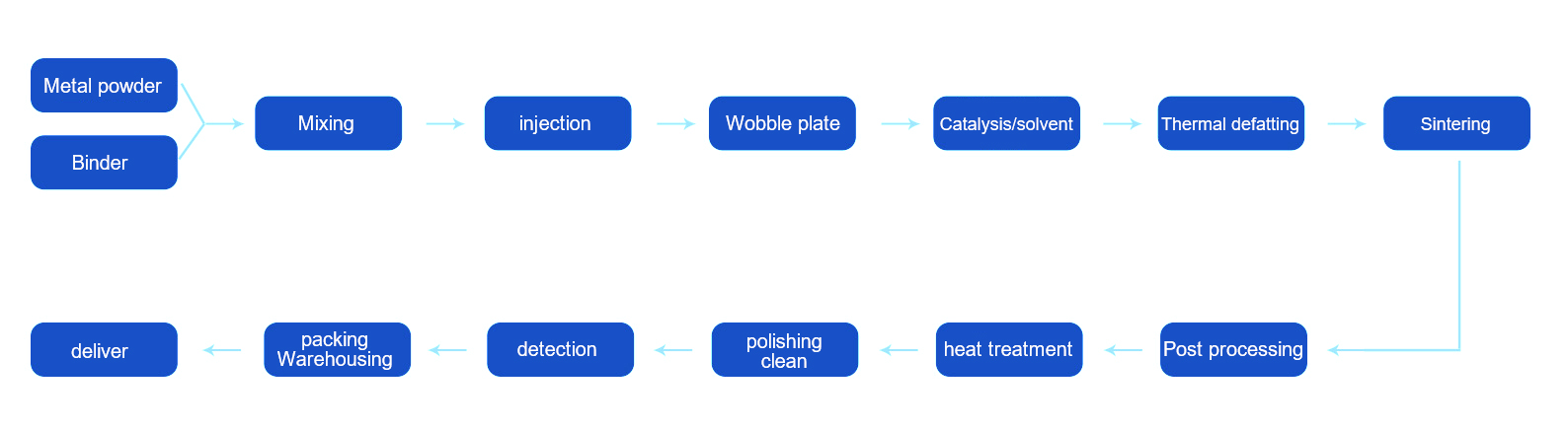

Process flow

Firstly, select metal powders and organic binders that meet the requirements of MIM, and mix them into a uniform feed using appropriate methods under certain temperature conditions. Then, after granulation, they are heated and plasticized

Inject the injection molding machine into the mold cavity to obtain the formed blank, then degrease it through chemical or solvent extraction methods, and finally sinter and densify to obtain the final product.